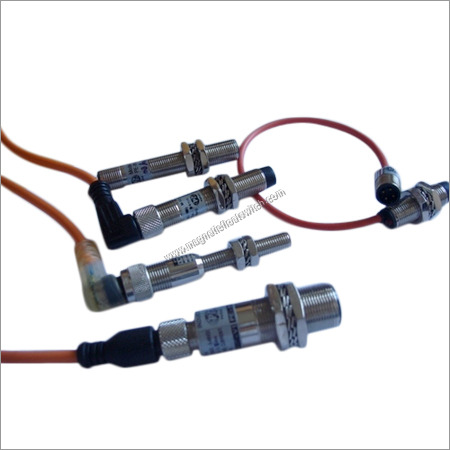

Inductive Proximity Switches

Price 550 INR/ Piece

Inductive Proximity Switches Specification

- Sensor Type

- PROXIMITY SWITCHES

- Current

- 300AMP Ampere (amp)

- Product Type

- PROXIMITY SWITCHES

- Operating Temperature

- -5-75 Celsius (oC)

- Working Temperature

- -5-75 Celsius (oC)

- Application

- MEATAL INTDUSTRIES USED

- Warranty

- 1 YEAR MANUFACTURING

Inductive Proximity Switches Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 50 Pieces Per Day

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- International norms. Each piece is packed in separate bubble polythene bag and then in individual corrugated box. As per

- Main Domestic Market

- All India

- Certifications

- CE APPROVED

About Inductive Proximity Switches

- Size : M-18X50

- Type : Pnp

- Output Logic : No

- Operating Voltage : 5-40 Vdc

- Max. Load Curren : 300 Mamp.

- Sensing Distance : 8.0Mm For Standard Object Size

- Switching Frequency : 250 Hz.

- Voltage Drop At Full Load : 2.5 Vdc

- No Load Current : >10.0 Mamp.

- Residual Current : 0.001 Mamp.

- Position Indication : Led

- Cable : 3 Core Pvc & Pu Flexible

- H.V. Test : 1.5 Kv For 1 Sec.

- Ambient Temp. : 700 C

- Enclosure : Nickel Platted Brass Tube

- Probe Size : M-18X50

- Mounting : Non Flush Type

- Protection Grade : Ip-67

- Approvals : Ce

- Standard object Size : 20X20X1 Mm

The Proximity Switches Dc Type Are Available In Pnp / Npn Type And Logic Available No / Nc & No+Nc, 2 Wire , 3Wire And 4 Wire.

Working Principal

An Inductive Alternating R.F. Field Is Developed At The Front Of The Sensing Surface Of The Proximity Switch. This Field Is Generated By The Resonant Circuit Coil Of The Oscillator.

Energy Is Absorbed When A Metal Piece Is Brought Into The R.F. Field Near The Sensing Surface, Causing Oscillation To Stop. Hence The Demodulated Voltage Feeding The Trigger Disappears.

For Dc Switches

The Trigger Operates Rapidly When Oscillation Stops And This Trigger Switches The Output Transister, Which Can Be Either Npn Or Pnp To Drive An Electronic Circuit Or Relay.

For Ac Switches

A Thyristor Is Triggered When Oscillation Stops Due To The Presence Of Metal . This Thyristor Is Connected In Series With A Bridge And This Series Combination Is Connected To The Ac Load.

Advantages Of Proximity Switches

- These Switches Can Be Used Anywhere Where Extreme Conditions Exist, E.G.

- With Lubricants And Cutting Oils

- Under Vibration

- Environments Where Water And Steam Are Present

- Dusty Environments, Etc.

Inductive Proximity Switches Or Sensors Are Primarily Used When The Object To Be Sensed Is Metallic, That Is Inductive Proximity Switches Are Used To Detect The Position Of Metals (Any Type). Some Applications Of Inductive Proximity Switches Are Machine Tools, Textile, Sugar, Cement, Automobile Industries And Many More.

High Performance in Demanding Environments

These proximity switches excel in harsh metal industry conditions due to their wide operating temperature range from -5C to 75C and robust build. Their reliability minimizes downtime and supports continuous operation of critical processes.

Safe and Efficient Non-Contact Sensing

Utilizing inductive technology, these switches detect metal objects without physical contact, reducing wear and tear on components. Their high current tolerance ensures safe and efficient integration into heavy-duty industrial systems.

FAQs of Inductive Proximity Switches:

Q: How do Inductive Proximity Switches work in metal industry applications?

A: Inductive Proximity Switches detect metallic objects without contact by generating an electromagnetic field. When a metal object enters this field, the switch activates, making them ideal for automation and safety in metal manufacturing processes.Q: What are the benefits of using these switches with a current rating of 300AMP?

A: A 300AMP current rating ensures that these switches handle high-power industrial equipment safely, minimizing risks of overload and offering compatibility with robust machinery typically found in metal industries.Q: When should these proximity switches be installed in industrial workflows?

A: Install these proximity switches during system setup or maintenance periods, especially when upgrading or automating metal processing lines to enhance detection accuracy and operational reliability.Q: Where can the switches be sourced from?

A: The switches can be sourced directly from manufacturers, exporters, suppliers, and wholesalers based in India, allowing buyers to access quality products backed by a 1-year manufacturing warranty.Q: What is the recommended process for integrating these sensors into existing equipment?

A: Integration involves securely mounting the switches at critical detection points, wiring them according to the provided schematic, and calibrating the sensor for the specific metal object sizes encountered in your workflow.Q: In what ways does the 1-year warranty benefit customers?

A: The 1-year manufacturing warranty assures buyers of product reliability, covering any defects or malfunctions within the warranty period. This reduces maintenance costs and instills confidence in industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inductive Proximity Switches DC Type Category

Inductive Proximity Switch

Price 550 INR / Piece

Minimum Order Quantity : 10 Pieces

Warranty : 1 YEAR MANUFACTURING

Product Type : Inductive Proximity Sensor

Working Temperature : 575 Celsius (oC)

Operating Temperature : 575 Celsius (oC)

Inductive Proximity Switch Connector type

Price 495 INR / Piece

Minimum Order Quantity : 10 Pieces

Warranty : 1 YEAR MANUFACTURING

Product Type : PROXIMITY SWITCHES

Working Temperature : 575 Celsius (oC)

Operating Temperature : 575 Celsius (oC)

Connecting Cables for Connector type sensors

Price 495 INR / Piece

Minimum Order Quantity : 10

Warranty : 1 YEAR MANUFACTURING

Product Type : CONNECTING CABLE

Working Temperature : 575 Celsius (oC)

Operating Temperature : 575 Celsius (oC)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS